Our sustainability work

Sustainability. What could be more important?

Since 2013, we have been baking completely fossil-free. Already in 1953 we started heating the bakery with recycled heat from the ovens. Sustainability has been a tradition for us since our family started baking crispbread in the early 1800s. It’s all about what we leave behind for our children, isn’t it?

Sustainability is our tradition

So that six generations of bakers can one day become seven, and then eight, nine and ten, sustainability is an important tradition for us. To make you and us feel good, we bake just like our great-grandmother Jacobs Karin, using only natural ingredients, water from our own spring and never more than what nature gives us. For us, it’s all about what we leave behind for our children.

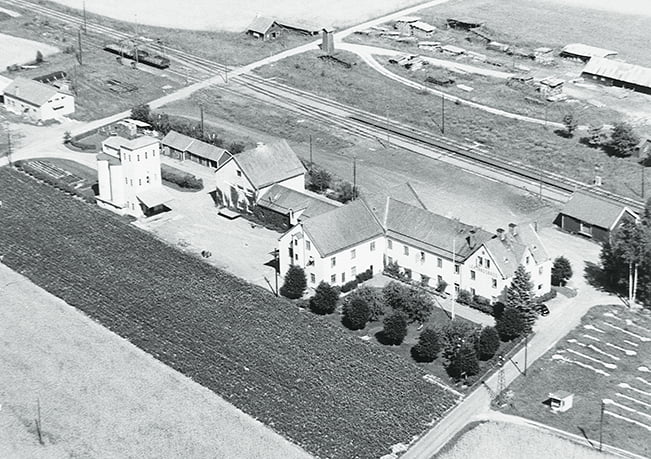

We started heating the bakery and the hot water with recovered heat from the ovens back in 1953, and since 2013 we have been baking exclusively with renewable energy – in Dalarna we have fantastic nature and therefore we can run the entire bakery with wind and hydropower from the nature around us. The heat is retained inside the bakery by building the walls twice as thick.

As a family business, we don’t look at quarterly economics – we look at centuries. We have had energy declarations since the 1980s and the packaging shows the carbon footprint of the bread. The carbon footprint includes everything. From the production of fertilizer for the fields, the cables that run the power to our bakery, the energy to make the paper for our packaging, the fuel for the tractors, the trucks…well, you get the picture – everything you need to make a climate-smart choice in the store.

Even higher requirements than we need

In Sweden, the demands on agriculture are high, but Leksands Knäckebröd sets even higher standards.

Rye is inherently challenging to grow. If it rains at the wrong time, the harvest can fail, and then it cannot be used to make good flour; the rye becomes animal feed instead. Leksand’s crispbread uses only Swedish grain. The rye, which is the basic ingredient in most of our crispbread has traveled at most 34 miles. We work with farmers and demand more from them than the most tightly controlled agriculture in the world, namely Swedish agriculture. Even all other grains are as locally produced as possible so that we get short transportation and reduce the environmental impact while we support the local farmers.

Leksands Crispbread only buys cereals with the origin label “Från Sverige” (From Sweden), which means that the growers comply with strict Swedish legislation. We never use additives or bakery aids. The few ingredients that are listed on the packaging are what really is in the bread.

Our sustainability journey

1953

First heat exchanger is installed.

1982

All investments are subject to life cycle analysis.

1997

Leksands Knäckebröd becomes environmentally certified.

2013

The bakery will be completely fossil-free.

2021

We introduce climate accounting on our crispbread.

Recovering waste from dough and bread

What do the numbers on the packaging mean?

On most of our crispbread, there is a figure that tells you how much carbon dioxide equivalent (CO2e) such a package has created. That is, all greenhouse gases converted to the effect of carbon dioxide on the climate, from field to store.

Which for our blue Normalbaked crispbread is 0.40 kg. And then we’ve taken everything into account. From the production of fertilizer for the fields, the cables that run the power to our bakery, the energy to make the paper for our packaging, the fuel for the tractors, the trucks…well, you get the picture – everything you need to make a climate-smart choice in the store.

How did we arrive at these figures?

To calculate the carbon footprint of our production, we enlisted the help of the analysis company U&We. They have extensive experience in helping companies with sustainability issues. This includes identifying the impact of the activity on the environment. Read more about our cooperation with U&We here.

Sustainability report

We have compiled all calculations in our sustainability report. We update this every year. You can read it by downloading it below.